GlobalFoundries Obtains Funding For GaN Production

Separately, a new JV fab breaks ground, while 3.5D packaging emerges.

By Mark LaPedus

GlobalFoundries (GF) has received an additional $9.5 million in federal funding from the U.S. government to propel the development of its efforts in the gallium nitride (GaN) market.

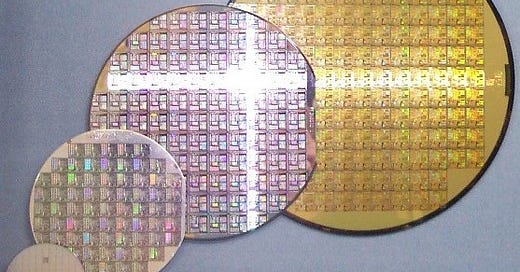

GF is developing a 200mm GaN-on-silicon manufacturing capability within its fab in Essex Junction, Vt. With the ability to handle high voltages and temperatures, GaN chip technology enables higher performance and greater energy efficiency across a range of RF and high-power control applications, including automobiles, datacenters, IoT, aerospace and defense.

With the award, GF will continue to add new tools, equipment and prototyping capabilities to its GaN IP portfolio and reliability testing as the company moves closer to full-scale manufacturing of its 200mm GaN chips in Vermont.

The new funding, awarded by the U.S. Department of Defense’s Trusted Access Program Office, represents the latest federal investments to support GF’s GaN program. In total, GF has received more than $80 million from the U.S. government for its GaN efforts.

GF’s Vermont-based fab is a U.S.-accredited Trusted Foundry and the global hub of GF’s GaN program. This accreditation distinguishes GF as a trusted manufacturer of chips for U.S. military and aerospace applications.

This program is administered by the Defense Microelectronics Activity (DMEA) organization on behalf of the U.S. Department of Defense (DoD). “This strategic investment in critical technologies strengthens our domestic ecosystem and national security, and ensures these assets are readily available and secure for DoD utilization,” said Nicholas Martin, director of the DMEA.

GF is making a big push in GaN. In July 2024, GF acquired Tagore Technology’s GaN power portfolio and created the GF Kolkata Power Center in Kolkata, India.

More news

In other foundry news, VisionPower Semiconductor Manufacturing Co. (VSMC), a joint venture formed by Taiwan’s Vanguard International Semiconductor Corp. and NXP of the Netherlands, has broke ground at the site of its new 300mm fab in Tampines, Singapore. With a total investment of approximately $7.8 billion, the new facility is anticipated to begin initial production in 2027.

Meanwhile, X-FAB Silicon Foundries has announced a new embedded memory offering. Fabricated on its high-voltage BCD-on-SOI XT011 platform, X-FAB can supply customers with an AECQ100 Grade-0 compliant 32KByte capacity embedded flash IP, combined with an additional 4Kbit EEPROM—all implemented on a 110nm process node. Larger cuts of 64 and 128KByte flash and larger EEPROM are planned from 2025 onwards.

On the packaging front, Broadcom has announced what the company calls a 3.5D packaging technology. Broadcom announced the availability of its 3.5D eXtreme Dimension System in Package (XDSiP) platform technology. The technology combines 2.5D packaging with 3D-IC integration and face-to-face technology.

Broadcom’s lead 3.5D XPU integrates four compute dies, one I/O die, and six high-bandwidth memory (HBM) modules, leveraging TSMC's 2.5D packaging technologies.