SkyWater acquires Infineon’s 200mm Fab In U.S.

The move expands SkyWater’s foundry capacity with new capabilities.

By Mark LaPedus

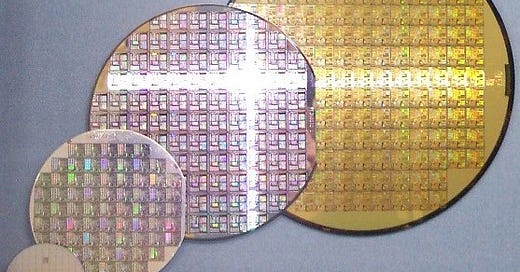

In a major move, SkyWater Technology, a U.S.-based foundry vendor, has acquired Infineon’s 200mm fab in Austin, Texas.

The transaction involves Infineon’s Fab 25 facility in Austin. All workers at Fab 25 will become SkyWater employees as part of the agreement. The fab includes nearly 1,000 manufacturing jobs.

In addition, SkyWater and Infineon have formed a corresponding long-term supply agreement. Furthermore, SkyWater plans to transition the Fab 25 business model from an integrated device manufacturer (IDM) to a foundry fab, thereby increasing the available capacity in the U.S. for chips on nodes from 130nm to 65nm. These chips are critical for industrial, automotive and defense applications.

Fab 25 will also increase SkyWater’s scale as a foundry and provides additional capabilities, such as a 65nm process, expanded copper processing, and high-voltage Bipolar-CMOS-DMOS (BCD) technology.

“This milestone expands our partnership with Infineon and significantly increases our U.S. foundry capacity,” said Thomas Sonderman, chief executive of SkyWater, based in Bloomington, Minn.

The closing of the transaction is subject to regulatory approval in the U.S. and is expected in the coming months.

SkyWater provides foundry services in 200mm fabs. The company’s foundry model streamlines the path to production for chips at more mature nodes. This model enables the development of chips for various applications, such as mixed-signal CMOS, ROICs, rad-hard ICs, power discretes, MEMS, superconducting ICs, photonics, carbon nanotubes and interposers.

Infineon’s expands too

Meanwhile, Infineon is also expanding its fab footprint despite selling its U.S. facility. Infineon says it has recently made progress on its 200mm silicon carbide (SiC) roadmap. The company will release its first products based on 200mm SiC technology to customers in the first quarter of 2025.

The products, manufactured within its Villach, Austria fab, provide SiC power technology for high-voltage applications, including renewable energy, trains, and electric vehicles.

Additionally, the transition of Infineon's fab site in Kulim, Malaysia, from 150mm wafers to the larger and more efficient 200mm diameter wafers is on track. The newly built Module 3 is poised to commence high-volume production aligned with market demand.

In addition, the European Commission has recently approved funding for Infineon’s new power device fab in Dresden, Germany. The fab opening is planned for 2026.

Last year, Infineon developed the world’s first 300mm power gallium nitride (GaN) wafer technology.